R&D Plastics - "Award Winning Customer Support"

R&D Plastics has provided a wide range of plastic parts manufacturing methods as well as assembly, part decorating, and secondary operations.

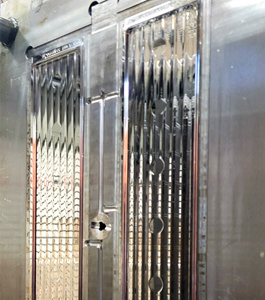

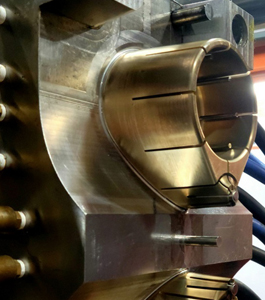

In manufacturing large-scale plastic parts, two key techniques dominate: low-pressure structural foam molding and high-pressure injection molding. Each method brings its own strengths and ideal applications, so understanding their differences is essential when choosing the right manufacturing route. High-Pressure Injection Molding By contrast, high-pressure injection molding begins with resin pellets melted and then forced into a mold cavity via a high-pressure nozzle. This process enables fin...

Our plastics production team specializes in complex, custom solutions. With upfront mold design and engineering capabilities, and 15 machines ranging from 25 tons to 1300 tons for new projects or transfer opportunities, R&D can meet your most challenging needs with economical costs, fast turnaro...

Read More

Our plastics production team specializes in complex, custom solutions. With upfront mold design and engineering capabilities, and 15 machines ranging from 25 tons to 1300 tons for new projects or transfer opportunities, R&D can meet your most challenging needs with economical costs, fast turnaro...

Read More

Our plastics production team specializes in complex, custom solutions. With upfront mold design and engineering capabilities, and 15 machines ranging from 25 tons to 1300 tons for new projects or transfer opportunities, R&D can meet your most challenging needs with economical costs, fast turnaro...

Read More

For more than 30 years, R&D Plastics has provided a wide range of plastic parts manufacturing methods as well as assembly, part decorating, and secondary operations.

For more than 30 years, R&D Plastics has provided a wide range of plastic parts manufacturing methods as well as assembly, part decorating, and secondary operations.

For more than 30 years, R&D Plastics has provided a wide range of plastic parts manufacturing methods as well as assembly, part decorating, and secondary operations.